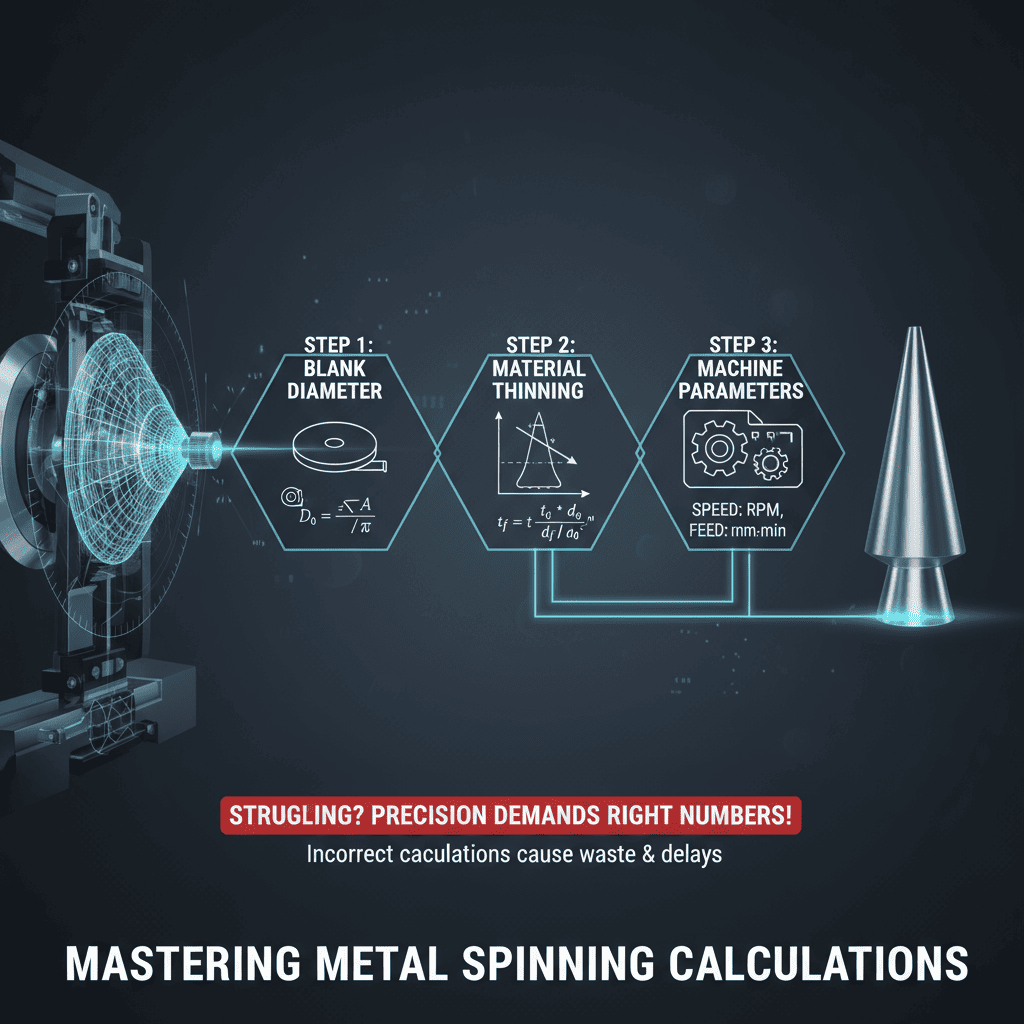

Struggling with parts that don't meet spec? Incorrect calculations can cause material waste and project delays. Precision metal spinning1 demands getting the numbers right from the very start.

Mastering metal spinning calculations involves three key steps. First, accurately determine the starting blank diameter2 based on the final part's surface area. Next, predict material thinning3 to ensure wall thickness meets specifications. Finally, set the correct CNC machine parameters4 for speed and feed rate5.

Getting these calculations right is the difference between a perfect component and a piece of scrap. I remember a client who came to us with a complex venturi tube design6 that their previous supplier kept failing. The issue wasn't the machine; it was the initial math. They miscalculated the blank size and thinning rates. It taught me that precision starts long before the metal even touches the machine. Let's break down how we approach these critical calculations.

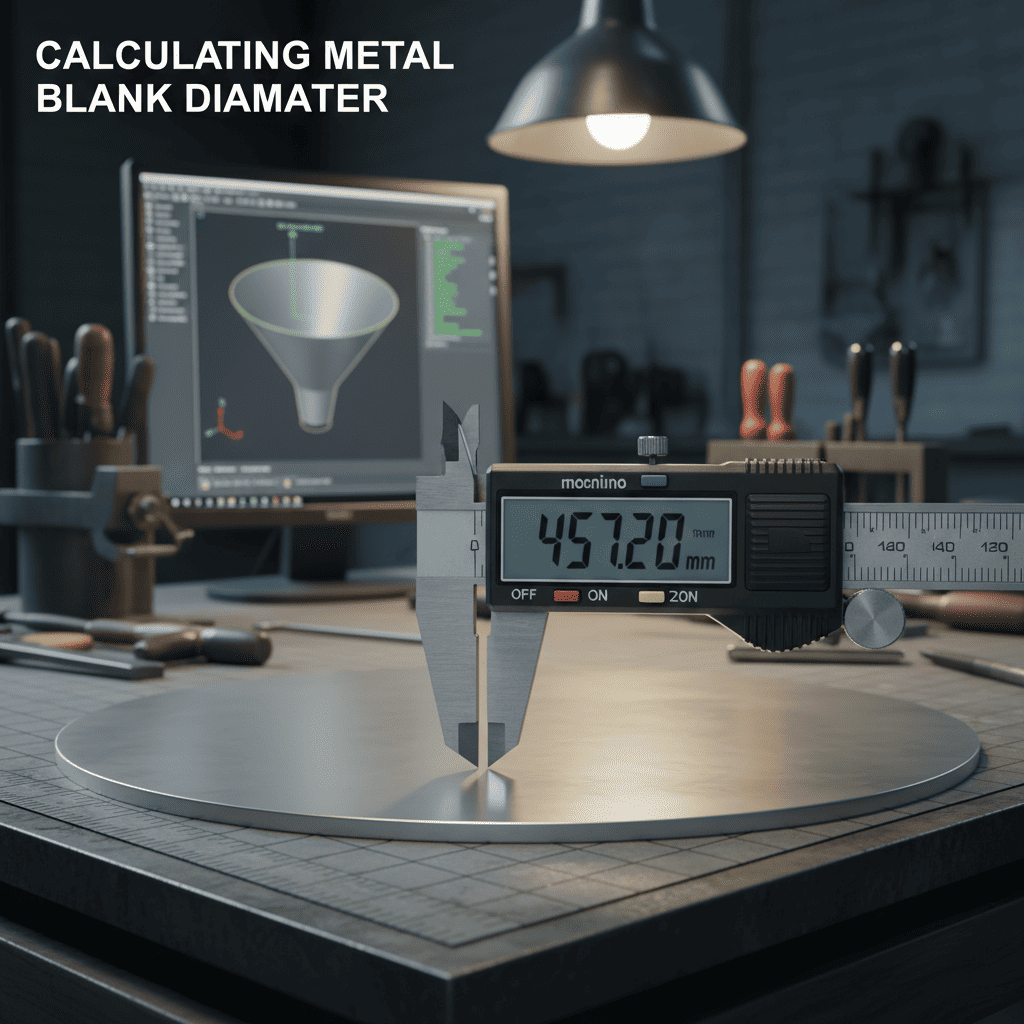

How Do You Calculate the Starting Blank Diameter?

Wasting expensive material on blanks that are too large? Or finding your part is too small? Guessing the blank size is a costly mistake in CNC metal spinning.

Calculate the starting blank diameter2 by finding the surface area of your final spun part. For simple shapes like cones or cylinders, you can use geometric formulas7. For complex profiles, CAD software8 is used to accurately measure the surface area and calculate the required flat disc diameter.

This is the first and most fundamental step. If you get it wrong, everything else fails. The basic idea is that the surface area of the starting flat disc, which we call the blank, must equal the surface area of the final 3D part. For us, this calculation is a two-part process depending on the complexity of the component.

For Simple, Standard Shapes

When a customer needs a straightforward part like a cone, hemisphere, or cylinder, we often start with proven geometric formulas7. It's a quick and reliable way to get an accurate starting point.

| Shape | Formula for Surface Area (A) |

|---|---|

| Cone | π r (r + √(h² + r²)) |

| Hemisphere | 2 π r² |

| Cylinder Wall | 2 π r * h |

Once we have the surface area (A), we calculate the blank's diameter (D) using the formula for a circle's area: A = π * (D/2)². It's classic math, but it forms the foundation of efficiency.

For Complex Custom Parts

This is where our real expertise shines. For parts with multiple curves, flanges, and steps, simple formulas won't work. We use advanced CAD software to import the client's 3D model. The software precisely calculates the total surface area of the most complex designs. This data allows us to determine the exact blank diameter needed, minimizing waste and ensuring the final part can be formed completely. This is how we confidently handle intricate parts like aerospace components or custom fluid dynamics hardware.

How Do You Predict Material Thinning and Forming Forces?

Is your final part too thin and weak? Or does it fail to meet the required wall thickness? Uncontrolled material thinning3 is a common failure point in metal spinning.

*Predicting material thinning3 is based on the sine law9 (t₁ = t₀ sin α), where final thickness (t₁) depends on the initial thickness (t₀) and the forming angle (α). For complex parts, our self-developed CNC software10 simulates the process to ensure thickness consistency and calculate the required machine forces.**

Once we have the blank size, the next critical calculation is managing how the material thins out as it's formed. Metal spinning, by its nature, stretches and thins the material. Controlling this is key to the part's structural integrity.

The Sine Law in Action

The "sine law9" is a core principle in shear forming, a type of spinning. It states that the final wall thickness is a direct function of the angle at which the material is being formed. A steeper angle results in more thinning. For a simple cone, the formula is straightforward: t₁ = t₀ * sin α, where t₁ is the final thickness, t₀ is the original blank thickness, and α is the half-angle of the cone. If we're making a 30-degree cone, the wall will thin to about 50% of the original thickness. We use this calculation to select the correct starting material gauge to guarantee the final part meets its strength and thickness specifications.

Calculating Forming Forces

Knowing the thinning also helps us calculate the forces our machines will need to exert. Materials like stainless steel or titanium require immense force compared to aluminum. Our combination of German Leifeld machines11 and our own self-developed CNC spinning lathes gives us a huge advantage. We have the power for thick, tough materials and the precise control needed for delicate ones. Our custom software allows us to pre-program these force calculations, ensuring a smooth and stable forming process from start to finish, which is critical for achieving batch-to-batch consistency12.

How Do You Calculate for Precision Down to ±0.01 mm?

Are you struggling with inconsistent parts across a large production run? Achieving high precision requires more than just a good machine; it demands a system of calculation and control.

Achieving ±0.01 mm precision13 comes from calculating and controlling the entire process. This includes programming exact CNC toolpaths, setting precise spindle speed14s and feed rates, and using CMM measurements as a feedback loop to refine machine parameters for ultimate accuracy and consistency.

This is where art meets science. A specification of ±0.01 mm doesn't leave any room for error. It’s a tolerance that many shops can't hold, especially on an industrial scale. For us, it's not one single calculation but a system of interlocking calculations and process controls.

Calculating Machine Parameters

The finish and accuracy of a part are directly influenced by the spindle speed14 and the feed rate of the forming roller. There's a sweet spot for every material and thickness.

- Spindle Speed (RPM): Too slow, and the forming process can be unstable. Too fast, and you can introduce excessive heat and material stress. We calculate the optimal surface speed based on the material type and diameter.

- Feed Rate (mm/rev): This determines how quickly the roller moves along the part. A slower feed rate5 generally produces a smoother surface finish and better dimensional accuracy.

We have built a massive internal database of these parameters from thousands of projects. Our self-developed CNC machines allow us to fine-tune these calculations with a level of control that standard machines don't offer.

The CMM Feedback Loop

Calculations get you close, but measurement gets you to perfection. Our Coordinate Measuring Machines (CMMs)15 are central to our precision process. After the initial parts of a run are produced, they go straight to the CMM. The machine measures hundreds of points on the part's surface and compares them to the original CAD model. If there is any deviation, even by a few microns, we use that data to calculate micro-adjustments to the CNC toolpath or machine settings. This closed-loop feedback process is how we dial in and maintain ±0.01 mm accuracy across thousands of identical parts.

Conclusion

Mastering metal spinning calculations for blank size, material thinning3, and machine parameters is essential. This mathematical precision, combined with advanced technology, is how we deliver flawless, consistent parts.

Reference

Understanding precision metal spinning is crucial for ensuring high-quality, accurate metal parts, reducing waste, and preventing project delays. ↩

Calculating the starting blank diameter accurately is essential to avoid material waste and ensure the final part meets specifications. ↩

Predicting material thinning helps maintain the structural integrity of the spun part, ensuring it meets the required wall thickness. ↩

Setting the correct CNC machine parameters is vital for achieving precision and consistency in metal spinning processes. ↩

Setting the correct feed rate is essential for achieving a smooth surface finish and dimensional accuracy in metal spinning. ↩

Understanding the challenges in spinning complex designs like venturi tubes helps in improving calculation accuracy and part quality. ↩

Using geometric formulas helps in determining the correct blank size for simple shapes, ensuring efficiency and accuracy. ↩

CAD software is essential for calculating surface areas of complex parts, ensuring precise blank size and reducing material waste. ↩

The sine law is crucial for predicting material thinning, ensuring the final part's thickness meets design specifications. ↩

Self-developed CNC software allows for customized control and precision, enhancing the quality and consistency of spun parts. ↩

German Leifeld machines provide the power and precision needed for handling tough materials, ensuring high-quality metal spinning. ↩

Achieving batch-to-batch consistency ensures that every part meets the same high standards, crucial for large production runs. ↩

Achieving ±0.01 mm precision ensures high-quality, consistent parts, which is critical for industrial applications. ↩

Determining the optimal spindle speed is key to maintaining stability and preventing material stress during metal spinning. ↩

CMMs provide precise measurements that help refine CNC settings, ensuring consistent accuracy in metal spinning. ↩

<sup id=](https://metalspinningproducts.com/wp-content/uploads/2025/11/1762051482754_download.png)