You want to pick the best way for your production. Deep drawing is good for making many parts. It works well for shapes that are hard to make. It is also good when you need parts to be very exact. Deep drawing costs less for each part. Metal spinning is better for making fewer parts. It is good if you want to change designs easily. Metal spinning lets you start quickly.

Use this guide to help you choose the right way for your project. Keep reading to find out which method fits your material, speed, and budget needs.

Key Takeaways

- Deep drawing works well for making many parts fast. It is good for making lots of parts that need to be exact and detailed. Pick deep drawing if you need to make many items at once.

- Metal spinning is better for making fewer parts. It lets you change designs quickly. Use metal spinning if you need to be flexible.

- Think about what metal you will use. Both methods work best with soft metals like aluminum and stainless steel.

- Deep drawing makes parts with even wall thickness. Metal spinning can make parts with walls that are not all the same thickness. Pick the one that fits your needs.

- Make a good plan for your project. Do not pick the wrong metal or forget to plan. This helps you save time and money.

Process Overview

Deep Drawing

Deep drawing shapes flat metal sheets into 3D parts. A punch pulls the metal into a die. You can make cylinders and domes from one piece. This means you do not need to weld or join parts. Deep drawing is best for making many parts fast.

Deep drawing helps you get very exact sizes. Tolerances can be as close as +/- 0.030”. Some parts can even reach +/- 0.010”. How accurate it is depends on the blank’s tolerance and the material you pick.

Aluminum, stainless steel, cold-rolled steel, copper, brass, and nickel silver alloy are common choices. Each metal has special benefits. Aluminum resists rust and bends easily. Stainless steel is strong and looks clean.

Here are the main steps in deep drawing:

- Pick and get the metal blank ready.

- Put the blank over the die.

- Use a punch to pull the metal into the die.

- Trim and finish the part if needed.

| Feature | Deep Drawing |

|---|---|

| Initial Development Costs | High |

| Production Efficiency | High |

| Suitable for Batch Production | Large batches |

| Complexity of Shapes | Can create complex shapes |

| Wall Thickness Consistency | Easier to estimate and achieve |

Metal Spinning

Metal spinning forms round parts from flat metal discs. The disc spins on a lathe and shapes against a mandrel with a roller tool. Metal spinning works well for small or medium batches. You can change designs quickly.

Here’s how you do metal spinning:

- Get the lathe ready and pick the sheet metal.

- Cut the metal into a blank and pick a mandrel.

- Secure the blank on the lathe and line it up.

- Spin the lathe and shape the metal with the roller tool.

- Smooth the surface with more passes.

- Add details and finish the part.

Metal spinning uses aluminum, stainless steel, copper, brass, mild steel, and titanium. Parts are light, strong, and resist rust. Wall thickness can change more than with deep drawing.

| Limitation Type | Description |

|---|---|

| Material Thickness Limitations | Manual spinning has trouble with thick materials. CNC can spin thicker but still faces problems. |

| Part Complexity Limitations | Best for parts that are round and even. Hard to make complex shapes. |

| Production Speed Limitations | Manual spinning takes a lot of work. CNC is faster but may not beat deep drawing. |

| Skill Dependency | Manual spinning needs skilled workers. CNC helps but still needs trained people. |

You pick metal spinning when you want to change designs, set up fast, and spend less at first.

Key Factors

Cost

When you plan your project, cost often comes first. You want to know how much you will spend on tools and production. Deep drawing usually needs expensive dies and setup. This makes it less attractive for small runs. However, if you make many parts, the cost per part drops a lot. Metal spinning uses simpler tools, so you pay less at the start. This makes it a smart choice for low or medium volumes.

Here is a table to help you compare costs:

| Process | Volume Type | Cost Implications |

|---|---|---|

| Deep Drawing | Low | Higher tooling costs, but lower labor costs for large runs. |

| Medium | More cost-effective as volume increases. | |

| High | Most efficient for high volumes, with very low per-unit costs. | |

| Metal Spinning | Low | Lower tooling costs, best for low volume. |

| Medium | Good for moderate volumes, balances tooling and production costs. | |

| High | Less efficient for high volumes, tooling costs can add up. |

You also need to think about what drives the cost. Deep drawing has higher tooling costs because you need multi-stage dies. Metal spinning uses a simple mandrel, so tooling costs stay low. Material waste is higher in deep drawing because you trim more metal.

| Cost Factor | Metal Spinning | Deep Drawing |

|---|---|---|

| Tooling Cost | Low | Medium |

| Per-Unit Cost | Medium (small batches) | Medium (annealing needed) |

| Material Utilization | High (low waste) | Low (trimming waste) |

Tip: For small runs, choose metal spinning to save on tooling. For big runs, deep drawing gives you the lowest cost per part.

Materials

You want to pick the right material for your part. Deep drawing works well with ductile metals like stainless steel, aluminum, carbon steel, copper, and brass. You should avoid brittle materials because they can crack. Metal spinning also uses ductile metals, such as aluminum, copper, brass, mild steel, and stainless steel. Both processes need metals that bend without breaking.

| Process | Compatible Materials | Limitations |

|---|---|---|

| Deep Drawing | Stainless steel, Aluminum, Carbon steel, Copper, Brass | Not for brittle materials |

| Metal Spinning | Aluminum, Copper, Brass, Mild steel, Stainless steel | Needs ductile metals; best for round shapes |

- Deep drawing is best for large numbers of shallow, cup-like parts.

- Metal spinning is more cost-effective for medium to large round parts with changing wall thickness.

Complexity

Part complexity can change your choice. Deep drawing lets you make deep and complex shapes, even when the height is more than the diameter. You may need several steps and machines, which can raise costs and waste. Metal spinning is great for round and cylindrical shapes. It handles complex curves well and keeps costs down for these forms.

Note: Deep drawing is better for deep, complex forms. Metal spinning is best for round, detailed shapes.

Speed

Production speed affects your timeline and budget. Deep drawing works fast, especially for big runs. You can make hundreds or thousands of parts each day. Metal spinning is slower if done by hand, but CNC spinning speeds things up for small to medium batches.

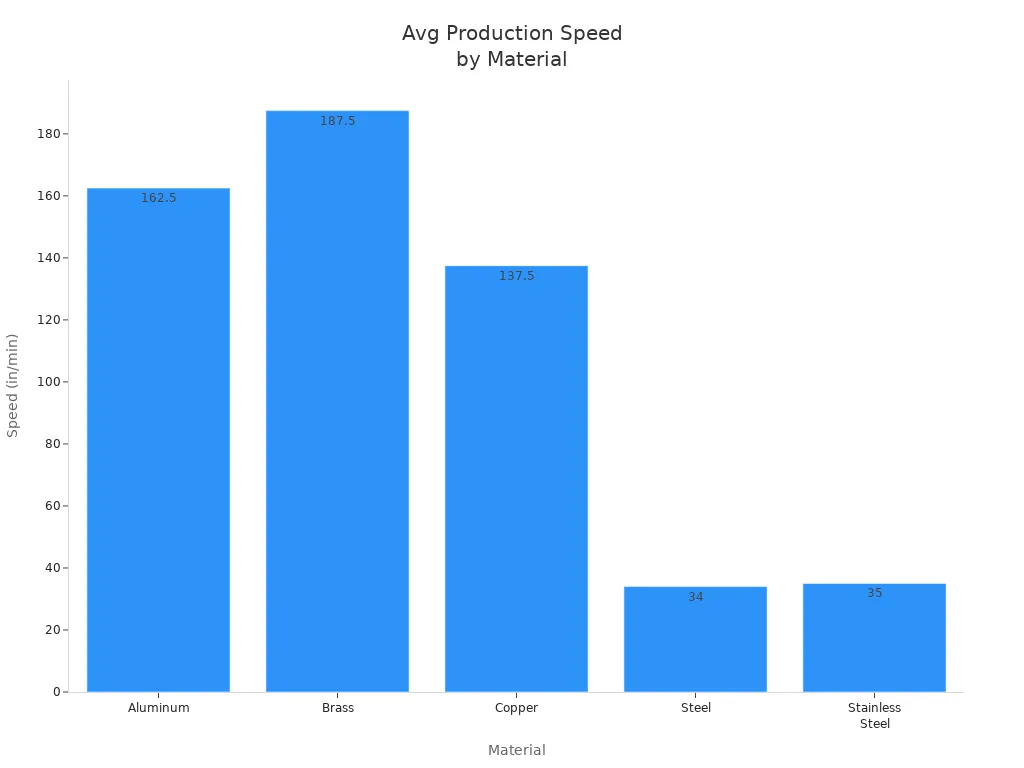

Here is a chart showing average speeds for different metals:

- Faster speeds mean lower labor costs and shorter lead times.

- Deep drawing is the best choice when you need many parts quickly.

Volume

You should match the process to your production volume. Deep drawing fits high-volume jobs. It is the best choice when you need thousands or millions of parts. Metal spinning is well-suited for low to medium volume production. It is ideal when you do not want to invest in expensive dies.

| Process | Typical Production Volumes | Applications and Limitations |

|---|---|---|

| Deep Drawing | High volume | Good for big shape changes, but needs ductile metals. |

| Metal Spinning | Low to medium volume | Best for round shapes, not cost-effective for high volumes. |

- Deep drawing allows for more complex shapes and higher reduction ratios.

- Metal spinning is often used when you do not want to pay for press tooling, especially for small runs.

Metal Spinning vs Deep Drawing

Wall Thickness

You want your parts to have the same wall thickness. Deep drawing helps you control wall thickness better. You can guess the thickness before you start. This process uses a die and punch to keep the metal even. The metal stays the same thickness as it stretches. You get parts with even walls, which is good for tight rules.

Metal spinning can make parts with different wall thicknesses. The roller tool shapes the metal as it spins, so the thickness can change. If you use manual spinning, the wall thickness can change even more. CNC spinning helps a bit, but you still see more changes than with deep drawing. If you want parts with different thicknesses in one piece, metal spinning is a good choice.

| Feature | Deep Drawing | Metal Spinning |

|---|---|---|

| Wall Thickness | Very consistent | Can vary across the part |

| Predictability | High | Medium |

| Best Use | Uniform walls, tight specs | Variable walls, custom specs |

Tip: Pick deep drawing if you need the same thickness everywhere. Choose metal spinning if you want different thicknesses in one part.

Stress Levels

You care about stress because it changes how strong your parts are. Deep drawing puts a lot of force on the metal. The punch pulls and stretches the blank, which can cause stress. You might need to heat the part to make it softer. This step helps stop cracks.

Metal spinning uses less force. The roller tool shapes the metal slowly as it spins. You see less stress in the finished part. Manual spinning makes even less stress, but it takes longer. CNC spinning is faster, but stress is still lower than deep drawing.

- Deep drawing: More stress, may need extra steps to fix it.

- Metal spinning: Less stress, less chance of cracks or breaks.

Note: If you want parts with less stress inside, metal spinning is safer.

Shape Capabilities

You want to know which process makes the shapes you need. Deep drawing makes complex 3D shapes. You can make cups, pans, domes, and other deep forms. It works well for parts with sharp corners and many features. You can add embossing and holes in one press, which saves time.

Metal spinning makes round shapes. You get parts like cones, cylinders, and hemispheres. The process can handle shapes with different diameters. It is hard to make complex 3D shapes this way. Metal spinning is best for round, smooth forms.

Here is a table showing what each process can do:

| Process | Unique Shapes Produced | Limitations in Shape Production |

|---|---|---|

| Deep Drawing | Larger, complex three-dimensional shapes (e.g., cups, pans, domes) | Cannot easily produce axisymmetric workpieces |

| Metal Spinning | Axisymmetric workpieces with multiple diameters | Less effective for complex three-dimensional shapes |

- Deep drawing is best for making lots of parts. You get exact and detailed shapes.

- Metal spinning lets you change designs fast. You make round parts with custom sizes.

If you need a part with deep, complex shapes, deep drawing is best. If you want a round part with different diameters, metal spinning is better.

Which Process Fits Your Needs?

- Pick deep drawing for:

- Making lots of parts

- Complex, multi-dimensional shapes

- Tight rules and even wall thickness

- Pick metal spinning for:

- Small to medium batches

- Round shapes

- Easy design changes and different wall thickness

You should match your process to your part’s shape, amount, and stress needs. This helps you save time and money and get the best results.

Comparison Table

It is easier to choose between deep drawing and metal spinning when you see them side by side. You want to know which one is better for cost, materials, shape, speed, and how many parts you need. The table below shows a quick look at both:

| Metric | Deep Drawing | Metal Spinning |

|---|---|---|

| Cost | Medium tooling cost, low per-part cost for large runs, more material waste | Low tooling cost, medium per-part cost, less waste |

| Material Compatibility | Works best with ductile metals like aluminum, stainless steel, copper, brass | Handles ductile metals, ideal for round shapes |

| Complexity | Makes deep, complex 3D shapes with tight tolerances | Creates round, freeform shapes, handles design changes easily |

| Speed | Fast for high volumes, uses stamping molds, needs annealing for some metals | Slower for single pieces, faster with CNC, best for short runs |

| Volume | Best for medium to large batches, efficient for mass production | Best for small to medium batches, flexible for prototypes |

| Surface Finish | Vertical stretch marks may appear | Circular spinning marks are common |

| Wall Thickness | Consistent, easy to predict | Can vary, allows custom thickness |

This table helps you pick the right process for your project. If you need lots of parts fast and want them to be very exact, deep drawing is a good choice. If you want to change designs, spend less at first, or make only a few parts, metal spinning is better.

Quick Tips:

- Use deep drawing for big batches and complex shapes with strict rules.

- Use metal spinning for small batches, round parts, or if you want to change designs fast.

This table lets you compare both ways quickly. Now you can choose which one fits your needs for cost, speed, and quality.

Applications

Deep Drawing Uses

Deep drawing is used in many fields. This process makes strong and exact parts from sheet metal. You use deep drawing when you need lots of parts. It is good for parts that must be very precise.

Here is a table that shows where deep drawing works best:

| Industry | Common Applications |

|---|---|

| Automotive | Oil pans, fuel tanks, body panels, exhaust components |

| Aerospace | Aircraft structural components, enclosures |

| Medical Devices | Instrument housings, surgical containers |

| Consumer Goods | Kitchenware, appliance housings, sinks, cans |

Car factories use deep drawing for body panels and oil pans. It helps make fuel tanks too. In aerospace, deep drawing shapes strong parts for planes. You use it for enclosures and other pieces. Medical device makers use deep drawing for instrument housings. They also make containers that must be clean and exact. You see deep drawing in kitchens. Cookware, sinks, and cans are made this way.

Tip: Pick deep drawing if you want many strong and exact parts. You save money when you make big batches. The parts last a long time.

Metal Spinning Uses

Metal spinning is used for round shapes and flexible designs. This process works well for small and medium batches. You can change the design fast. You can make parts with different wall thicknesses.

Here are common uses for metal spinning:

- Lighting reflectors and domes

- Mixing bowls and satellite dishes

- Funnels, hoppers, and cone-shaped fixtures

- Venturi tubes for dust collectors, fans, and air scrubbers

- Parabolic shapes for bell housings and antenna reflectors

- Cylinders for pipes, containers, and gas cylinders

- Hopper covers and bases from premium metals

- Tank heads for pressure vessels and storage tanks

Lighting factories use metal spinning for reflectors and domes. Food service uses it for mixing bowls and containers. Industrial plants use metal spinning for funnels and tubes. They also make tank heads this way. Aerospace uses metal spinning for antennas and housings with special shapes.

Note: Choose metal spinning for round parts and quick design changes. You get strong and light parts with less waste. Production is flexible and easy to adjust.

Examples

Automotive Parts

Deep drawing is used a lot in car factories. It helps make fuel tanks with hard shapes. You use high-grade aluminum alloy because it bends well and stays strong. You can make up to 100 fuel tanks every day. Each tank gets checked for size and leaks. These checks make sure tanks are safe and work well. You pick deep drawing when you need lots of exact and strong parts. This way saves time and lowers costs for big batches.

Deep drawing makes strong and light parts for cars. You meet safety rules and keep making parts fast.

Lighting Fixtures

Metal spinning is used to make many lighting fixtures. This way shapes round parts in many sizes and styles. You can make very big lampshades, even up to 120 inches wide. You pick metal spinning if you want to change designs fast or use different metals.

| Application Type | Description |

|---|---|

| Louvres and Shades | Made with metal spinning to spread light well. |

| Functional Gear Trays | Hold parts and can be the main part of a light. |

| Lighting Bollards | Need metal spun parts for caps and glare control louvres. |

- You can make lampshades in many shapes and sizes.

- Metal spinning works with aluminum, brass, copper, and steel.

- You get lights that look good and work well.

Metal spinning has been used in lighting for a long time. Skilled workers use it to make nice and useful lampshades. You pick metal spinning when you want to change designs and make small or medium batches. This way helps you fill custom orders and keep up with new lighting styles.

Metal spinning helps you make new designs fast and meet what customers want. You get strong and cool lights with less waste.

Decision Guide

Checklist

You need to pick the right process for your project. This checklist can help you choose between deep drawing and metal spinning. Experts say you should check each point before starting:

- Define your part shape and size.

Deep drawing is best for shapes that are deep or tricky. Metal spinning works well for round and even parts. - Estimate your production volume.

Deep drawing is good for making lots of parts. Metal spinning is better for small or medium amounts. - Review your material choice.

Stainless steel, aluminum, and brass work for both ways. Do not use hard metals that do not stretch for deep drawing. Thicker metals are easier to stretch. - Check wall thickness needs.

Deep drawing keeps the thickness the same. Metal spinning can make parts with different thicknesses. - Consider design flexibility.

Metal spinning lets you change designs fast. Deep drawing needs new dies if you want a new design. - Assess your budget for tooling.

Deep drawing costs more because it needs special dies. Metal spinning uses simple mandrels, so it costs less at first. - Think about forming speed.

Deep drawing is quick for big jobs. Metal spinning starts fast and is good for testing ideas. - Select the right press or lathe.

Use a press for deep drawing to control speed. Pick a manual or CNC lathe for spinning. - Decide on hot or cold forming.

Both ways can use hot or cold forming. It depends on your metal and what you want to make.

Tip: Metal spinning makes ridges that help make the part stronger, so you do not need as much work hardening.

Here is a table to help you compare your needs:

| Decision Point | Deep Drawing | Metal Spinning |

|---|---|---|

| Shape Complexity | Deep, complex shapes | Round, axisymmetric shapes |

| Volume | Large batches | Small to medium batches |

| Material Flexibility | Ductile metals, avoid hard ones | Ductile metals, versatile |

| Wall Thickness | Consistent | Variable |

| Design Changes | Slow, costly | Fast, easy |

| Tooling Cost | High | Low |

| Forming Speed | Fast for mass production | Quick setup, slower for large runs |

| Hot/Cold Forming | Both possible | Both possible |

Mistakes to Avoid

You want to stop mistakes that cost money when picking your metal forming process. Many people make the same errors. You can stop these problems by following expert tips:

- Skipping detailed planning.

Always make clear designs and check if your idea will work. If you do not plan, you waste time and money. - Choosing the wrong material.

Look at your metal choices. Make sure your metal fits your process and part. The wrong metal can crack or be weak. - Ignoring material thickness.

Thick metals stretch better in deep drawing. Thin metals can break or wrinkle. - Using the wrong forming method.

Pick the right tools and ways for your metal. Watch how your metal bends and shapes. - Cutting corners on cutting.

Use sharp and good tools for cutting. Bad cuts waste metal and ruin your parts. - Welding without proper prep.

Learn about welding steps. Clean and get surfaces ready for strong welds. - Measuring and marking poorly.

Use good tools. Check your measurements twice to stop mistakes. - Ignoring safety rules.

Train your team and follow safety steps. Safe work keeps everyone healthy and stops accidents.

Note: You can stop most mistakes by planning, picking the right metal, and using the right tools. Safety and being exact are just as important as speed and saving money.

Quick Reference Table: Common Mistakes and Solutions

| Mistake | How to Avoid It |

|---|---|

| Insufficient Planning | Make detailed designs and feasibility checks |

| Poor Material Choice | Research and test materials |

| Inappropriate Bending | Use correct tools and methods |

| Poor Cutting Techniques | Keep tools sharp and accurate |

| Welding Mistakes | Prepare surfaces and learn procedures |

| Inaccurate Measuring | Use precise instruments, double-check |

| Lack of Safety Precautions | Train staff, follow safety protocols |

Remember: Careful planning and smart choices help you get the best results. Take time to check each step before you start.

You can choose the best process by looking at your part shape, volume, material, and budget. Use the checklist to guide your decision.

- Review your needs for speed, cost, and design changes.

- Compare deep drawing and metal spinning using the tables above.

- Talk to a manufacturing expert or request a quote for your project.

Take action now. Pick the process that matches your goals and start your production with confidence.

FAQ

What shapes can you make with deep drawing and metal spinning?

You can make deep, complex shapes with deep drawing, like cups or pans. Metal spinning works best for round shapes, such as cones, domes, and cylinders. Use this table for a quick look:

| Process | Best Shapes |

|---|---|

| Deep Drawing | Cups, pans, domes |

| Metal Spinning | Cones, cylinders |

Which process is faster for making parts?

Deep drawing works faster for large batches. You can make thousands of parts each day. Metal spinning takes longer, especially by hand. CNC spinning speeds things up for small runs.

Tip: Choose deep drawing for speed when you need many parts.

Can you use both processes for the same project?

Yes, you can. Some projects use deep drawing for the main shape and metal spinning for finishing touches or special features. This mix gives you more design options.

How do you choose the right material?

Pick ductile metals like aluminum, copper, or stainless steel. These metals bend without breaking. Avoid brittle metals. Always check if your chosen metal fits your process and part needs.

What are common mistakes to avoid?

- Skipping detailed planning

- Picking the wrong metal

- Ignoring wall thickness

- Using the wrong forming method

Always plan, test materials, and use the right tools for best results.