You want to know which companies lead the way in metal spinning for 2025. This list helps you find reliable partners who deliver quality and stay ahead with new technology. When you choose a trusted supplier, your project gets better results and fewer problems. Industry experts picked these companies by looking at their reputation, skills, and impact. The global market for metal spinning machines is set to reach $105.14 million in 2025, with a steady growth rate of 3.26% through 2032. Use this guide to start your search for the right supplier.

- Global market size in 2025: $105.14 million

- Expected CAGR (2025-2032): 3.26%

Key Takeaways

- Metal spinning shapes metal into strong parts without seams. Many industries use it, like aerospace, automotive, and medical.

- Picking a good metal spinning supplier helps your project do better. Find companies with lots of experience, good tools, and helpful customer service.

- The world market for metal spinning may reach $105.14 million by 2025. This shows more people want high-quality metal parts.

- When you pick a supplier, check their certifications and material skills. Make sure they can make custom designs. This helps you get the right parts.

- Talking often and checking in with your supplier gives better results. This builds trust and keeps your project moving forward.

Metal Spinning Overview

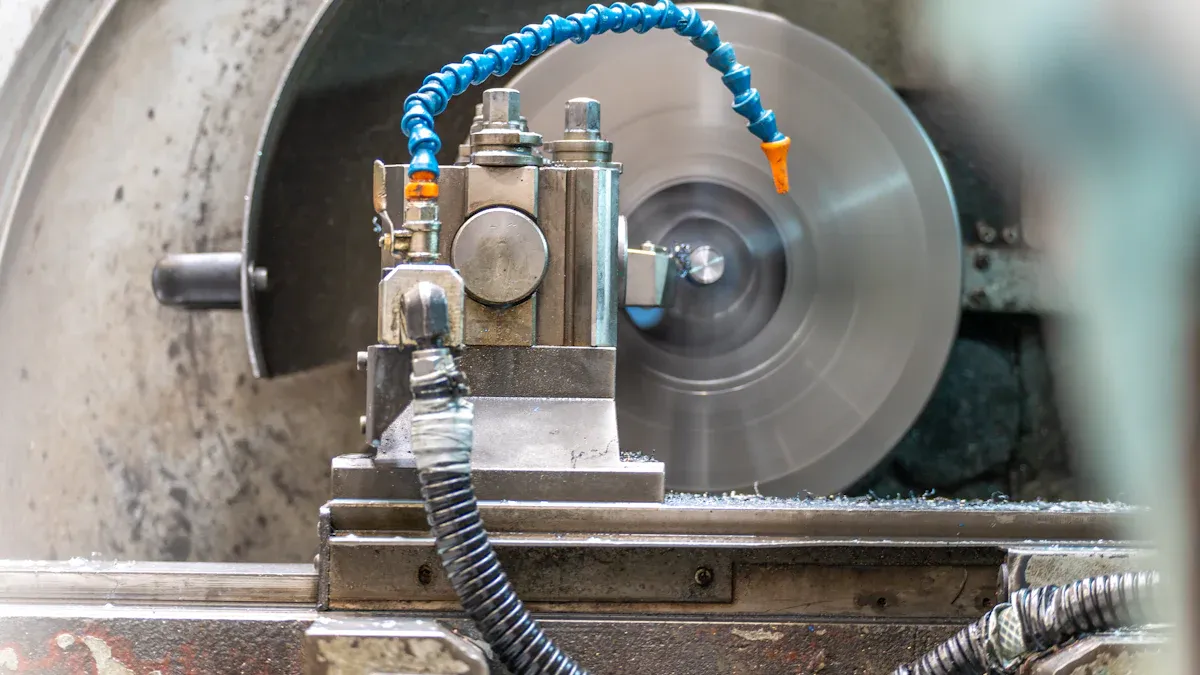

What Is Metal Spinning

Metal spinning is a way to shape metal. It uses flat metal discs. These discs spin very fast on a machine. A tool pushes the metal against a mold. This makes round, hollow parts. The shapes come out smooth and even. Metal spinning does not need seams or welds. This makes the parts strong. New technology has made metal spinning better. Automation helps lower mistakes. It also keeps production steady. CNC machines help make complex shapes. They are very accurate. Some machines use simulation software. You can see your design before making it. These changes help you get better parts faster.

Applications

Metal spinning is used in many fields. Here are some main examples:

- Aerospace: Engine parts and exhaust systems use metal spinning. These parts must be strong and exact.

- Automotive: Wheel rims and exhaust parts are made this way. They are light and last a long time.

- Medical: Surgical tools and devices need high precision. Metal spinning helps make them.

- Renewable Energy: Wind, solar, and hydro systems use spun metal parts. These parts help the systems work better.

- Lighting and Architecture: Modern lights and decorations use metal spinning.

Tip: Look around and you may see metal spinning in things like lamps or car parts.

Benefits

Metal spinning has many good points over other methods:

- You get parts that are strong and last long, almost like forged metal.

- The process uses less material, so there is less waste.

- Production is fast because there are no seams or welds.

- You can make shapes that are complex and very accurate.

- Every part comes out round and the same.

- You can control the size and width, even for big parts.

- The process works with many metal alloys, so you have more options.

If you want parts that are reliable and high quality, metal spinning is a smart pick.

Top 12 Metal Spinning Companies 2025

If you want to know who is best at metal spinning, these companies are easy to notice. They have strong skills, good technology, and helpful service. Here is more about each company. This can help you pick the one that fits your needs.

H & H Manufacturing & Metal Spinning, Inc.

H & H Manufacturing & Metal Spinning, Inc. is in the United States. They have been working since 1966. They use metals like steel, stainless steel, aluminum, brass, and copper. If you need special designs, they can change their tools for you. They care a lot about helping customers. They make lighting products too. You might like their old-style RLM lighting shades. They also make shiny air filter covers for motorcycles.

| Specialty/Strength | Description |

|---|---|

| Experience | Over 50 years in the business |

| Materials | Steel, stainless steel, aluminum, brass, copper |

| Flexibility | Custom tooling and designs |

| Focus | Lighting industry, unique motorcycle parts |

Wenzel Metal Spinning, Inc.

Wenzel Metal Spinning, Inc. is in the United States. They can make small or big orders. They work with many kinds of metals. They finish jobs quickly. Their team uses CNC machines. This means parts are made the same every time. If you need a few samples or lots of parts, they can help.

Hi-Craft Metal Spinning

Hi-Craft Metal Spinning started in 1955. They are in the United States. People trust them for good quality. They help many businesses. These include furniture, aerospace, food service, lighting, architecture, commercial, and industrial. If you want a company with lots of experience, Hi-Craft is a good pick.

- Industries served:

- Furniture

- Aerospace/Aircraft

- Food Service

- Lighting

- Architectural

- Commercial

- Industrial

Century Metal Spinning Co.

Century Metal Spinning Co. is in the United States. They are experts at close tolerance spinning. They make both samples and big orders. Their work is used in aerospace, defense, research, electronics, and industry. They use strong materials like titanium and stainless steel.

| Industry Served | Capabilities |

|---|---|

| Aerospace | Tight tolerances, prototypes, production |

| Defense | Radar spheres, custom components |

| R&D | Custom parts, decorative pieces |

| Electronics | Functional, high-quality spun products |

| Industrial | Versatile spinning, titanium, stainless steel |

Toledo Metal Spinning Company

Toledo Metal Spinning Company is in Ohio, USA. They make many kinds of spun metal parts. These can be small or very big. You can get regular or special parts from them. Their team uses new machines. This keeps quality high and wait times short.

Columbia Metal Spinning Co.

Columbia Metal Spinning Co. is important in the metal spinning world. They have been around a long time. They have a strong place in the market. If you want a company with good results, Columbia is a safe choice. They compete with METCOM Inc. and Precision Metal Spinning.

| Company Name | Market Position |

|---|---|

| Columbia Metal Spinning Co. | Key player |

| METCOM Inc. | Competitor |

| Precision Metal Spinning | Competitor |

Helander Metal Spinning Company

Helander Metal Spinning Company is in Illinois, USA. They use new technology like CNC machining and hydroforming. They can work with thick metals and big sizes. They make their own tools and polish parts in different ways. Helander has Nadcap accreditation. This means they meet tough rules for aerospace and defense.

Helander is proud to have Nadcap accreditation. This is special for aerospace and defense work.

| Technology/Process | Description |

|---|---|

| Metal Spinning | Up to 0.250″ thick, 100″ diameter |

| Hydroforming | 15″, 20″, 25″ presses |

| CNC Machining | 20 centers, +/-0.001″ tolerance |

| In-house Tooling | Efficient, high-quality production |

| Abrasive Polishing | 36 to 250 grit finishes |

| Welding | MIG, TIG, Nadcap accredited |

ACME Metal Spinning

ACME Metal Spinning is in the United States. They make spun metal parts for farms and electrical equipment. If you work in these areas, their products are strong and dependable.

| Product Lines | Customer Segments |

|---|---|

| Metal spun parts | Agriculture |

| Electrical equipment |

Leifeld Metal Spinning

Leifeld Metal Spinning is a top company from Germany. Their machines and technology are used in over 60 countries. These include the United States, China, and Russia. They work hard on new ideas and have a research center. Leifeld helps many industries, like cars and airplanes. They show new products at big trade shows.

| International Markets Served | Competitive Advantages |

|---|---|

| Germany | Strong focus on innovation |

| United States | Full service through product lifecycle |

| China | Advanced technology, many patents |

| Russia | |

| Over 60 countries | Global reach |

WF Maschinenbau Und Blechformtechnik

WF Maschinenbau Und Blechformtechnik is in Germany. They like to use new technology. They make special metal forming for e-mobility, pressure tanks, and defense. In 2025, they joined with MJC Engineering to make more new things. WF Maschinenbau built the strongest spinning machine ever. They have a patent that changed how hubs are made.

| Innovation Description | Date |

|---|---|

| Custom forming for e-mobility, defense | April 2025 |

| Joint venture with MJC Engineering | Feb 2025 |

| 30th anniversary of hub patent | Dec 2024 |

| World’s most powerful spinning machine | Feb 2024 |

| New spinning tech at Blechexpo | Oct 2023 |

Industrias Puigjaner

Industrias Puigjaner is a famous company from Spain. They make high-precision metal spinning and forming machines. Their machines are used in many factories in Europe and other places. They care about quality and new ideas. They help industries like cars, airplanes, and energy.

[Open Slot for Regional/International Leader]

You should watch companies from Asia-Pacific, South America, and the Middle East. Metal spinning is growing fast in these places. Here is a quick look at where companies are found:

| Region | Countries Included |

|---|---|

| North America | United States, Canada, Mexico |

| Europe | Germany, UK, France, Italy, Russia, Turkey |

| Asia-Pacific | China, Japan, Korea, India, Australia, Indonesia, Thailand, Philippines, Malaysia, Vietnam |

| South America | Brazil, Argentina, Colombia |

| Middle East and Africa | Saudi Arabia, UAE, Egypt, Nigeria, South Africa |

Note: ISO 9001:2015 is the most common certificate for top companies. It means they follow strict rules for quality and make reliable products.

Company Comparison

Key Differentiators

Metal spinning companies are not all the same. Some make special shapes for lighting and buildings. Others use strong metals for planes and defense. You may need exact parts for medical tools or tough pieces for cars. Every company has its own strengths.

Here are some things that make these companies different:

- Custom Capabilities: Some companies can make shapes or sizes that are unique. If you want something special, look for this skill.

- Industry Focus: Some companies work mostly with aerospace, cars, or medical parts. They know what each field needs.

- Certifications: The best companies have ISO 9001:2015 or Nadcap. These show they care about safety and quality.

- Technology: CNC machines, hydroforming, and simulation software help make better parts. You get less waste and more accuracy.

- Material Expertise: Some companies use titanium, stainless steel, or brass. This gives you more choices for your project.

Tip: If you need parts for planes, find companies with Nadcap and experience with strong metals.

Strengths Summary

You want to compare what each company does best. Here is a table that shows how their strengths match with different industries and products:

| Industry/Application | Key Products/Components | What You Should Look For |

|---|---|---|

| Aerospace & Defense | Rocket nose cones, engine parts, satellite housings | Strength, reliability, weight savings |

| Medical & Pharmaceutical | Filter housings, instrument cases, device enclosures | High precision, hygienic finishes |

| Food Processing & Appliances | Mixing bowls, pressure cookers, specialty cookware | Sanitary finishes, corrosion resistance |

| Lighting & Architecture | Light reflectors, decorative domes, architectural details | Custom shapes, aesthetic appeal |

| Automotive & Transportation | Wheel rims, brake components, fuel tanks | Strength, precision, high-volume |

| Musical Instruments | Brass bells, drum shells, cymbals | Resonance, uniform wall thickness |

| Industrial & Commercial | Funnels, hoppers, filter cartridges, ductwork | Fluid handling, air management |

Use this table to match your needs with the right company. If you want custom lighting, pick a company with design skills. If you need strong parts for planes, choose one with advanced certifications and metal expertise. This helps you find the best company and get good results.

Choosing a Metal Spinning Supplier

Selection Factors

Picking a good metal spinning supplier helps your project go well. You want a partner who listens and delivers on time. Here are some things to check:

- Experience matters. A supplier with many years can fix problems fast.

- Modern machines help make parts more exact and lower errors.

- Good reviews mean you can trust the company.

- Some suppliers care about the planet and recycle materials.

- Customer support is important. You want quick answers to questions.

- Location matters. A nearby supplier saves time and money.

- Fast delivery keeps your project moving.

Tip: Ask if they have strong quality checks. This helps you get good products.

You might face problems like late deliveries or parts that do not match. Many top suppliers use computers to track orders and check quality. They also train workers and do regular checks to stop mistakes.

| Challenge | How Suppliers Solve It |

|---|---|

| Supply Chain Management | Use computers to watch orders |

| Quality Inconsistencies | Set up strong checks for quality |

| Building Relationships | Do regular checks and work closely with partners |

Questions to Ask

When you talk to a metal spinning supplier, make sure they can do your job. Here are some smart questions:

- Can you make the parts I need?

- What material should I use for my project?

- What process works best for my project?

- Can you follow the rules I need?

You can also ask about delivery times, how they fix problems, and what help they give. These questions help you pick a supplier who fits your needs and keeps your project going well.

Picking the right metal spinning company helps you do well. When you look at suppliers, see how they talk with you and check their work. Here is a simple guide:

| Evaluation Criteria | Description |

|---|---|

| Establish Clear Communication | Talk often and know who to contact so you get updates. |

| Monitor Key Performance Indicators | Check quality, delivery, and how fast they answer to keep things going right. |

| Conduct Periodic Reviews and Audits | Look at their work and check it sometimes to make sure they do things your way. |

| Foster Collaboration | Work as a team and share ideas to build trust and get better results. |

To get the best results, try these tips: Ask experts for help. Learn how metal spinning works. Talk to teams who understand what you need.

When you work well with your supplier, you get better parts, good service, and maybe even new ideas for your products.

FAQ

What metals can you use for metal spinning?

You can use many metals for spinning. Common choices include aluminum, stainless steel, copper, and brass. Some companies also work with titanium or special alloys. Ask your supplier about the best metal for your project.

How do you know if metal spinning is right for your part?

If your part is round, hollow, or needs to be strong and seamless, metal spinning might work well. You can ask your supplier to review your design. They can tell you if spinning is a good fit.

Can you get custom shapes with metal spinning?

Yes, you can! Metal spinning lets you create custom shapes and sizes. You can ask for special designs or features. Some companies even help you with the design process.

How long does it take to get metal spun parts?

Lead times can change based on your order size and design. Simple parts may take a few days. Complex or large orders might take a few weeks. Always ask your supplier for a timeline.

Do you need special tools for every new part?

Most new parts need custom tooling. Your supplier will make a tool that matches your design. Some companies keep tools for repeat orders, so you save time and money next time.